Simulation and optimization helps you achieve highly productive results for live factory processes, both in the planning and operational phases.

- Highest ERP integration

- Continuous order navigation

- Cyclic production controlling

- Integrated staff planning

- Cloud based solutions

Applying the "Digital Factory" methods (see VDI 4499.x) is thereby the logical development of the following solutions:

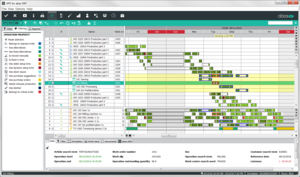

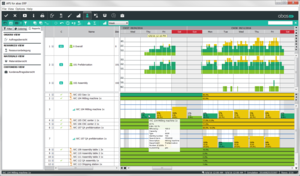

- Classic run-time process planning and APS solutions (integral part: see figure)

- Simulation modeling application

- Optimizing and organizing manufacturing processes according to analysis results

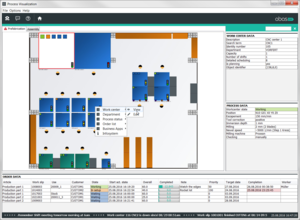

Our simulation models used for production planning and controlling correspond exactly to the models used for process optimization. This is an important feature of our approach, which has the "communication of things" according to IoT in focus. CPS data (PDC / MDC) is displayed based on process models in 2D or 3D, providing highly efficient process control using the most modern communication technology. Together with our customers, we are paving the way to the "digital factory" for highly efficient "smart manufacturing" in our INDUSTRY 4.0 FORUM.

As software systems developers, we remain committed to the following:

- Lean Management and Process Consulting

- Process development with abas ERP

- abas ERP and cyber-physical systems as a further development of the classic MES approach

- High quality process data acquisition with PDA, MDA and modern HMI systems

- Supporting the automation process

Want more information?

Request information tailored to your needs.